LGThe client's washing machine was not working; right after starting, an LE message appeared. The cause of the malfunction was a hall sensor that had stopped working properly. We replaced the sensor, and now the machine is working perfectly.

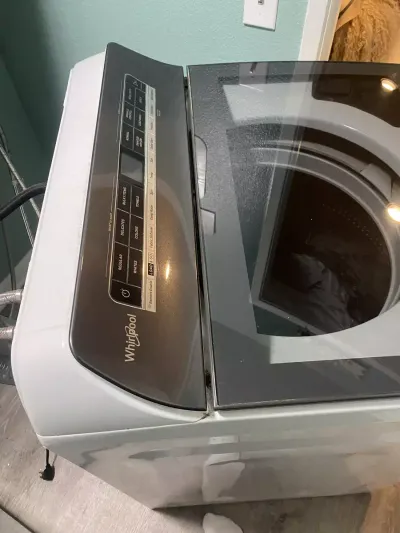

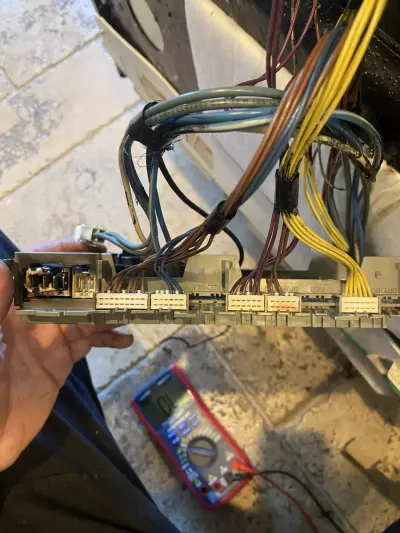

WhirlpoolThe washing machine stopped working completely. First, we checked if there was voltage in the network. Next, we checked if electricity was reaching the control board. It was coming, but the machine did not respond to button presses or knob turns. There is often an indication on the control board that shows whether the board is working or not. It turned out that the problem was with the user interface board. Replacing the user interface board cured this washing machine.

GEThe client reported a leak. It turned out that one of the suspension rods was broken, causing strong vibrations during operation and partial dislodging of a return tube, which spilled liquid onto the floor. We replaced the suspension, repositioned the tube, and securely fastened it.

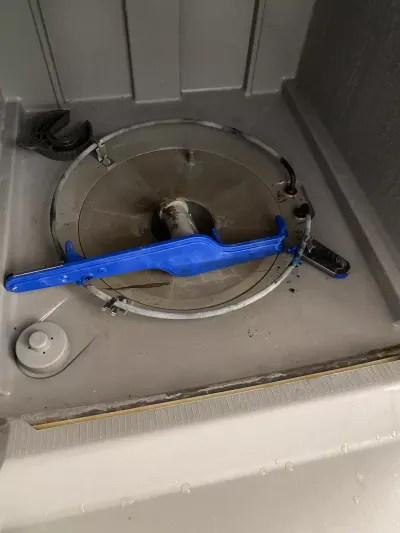

SamsungThe client noticed small sticky dirt particles remaining on the clothes and at the bottom of the washing machine after washing. The client used special cleaning agents for the washing machine, but unfortunately, this did not help. Also, he noted a bad smell coming from the washing machine. We found that dirt had accumulated under the agitator of the washing machine. We replaced the agitator (as it was not possible to clean it well) and cleaned the dirt beneath it.

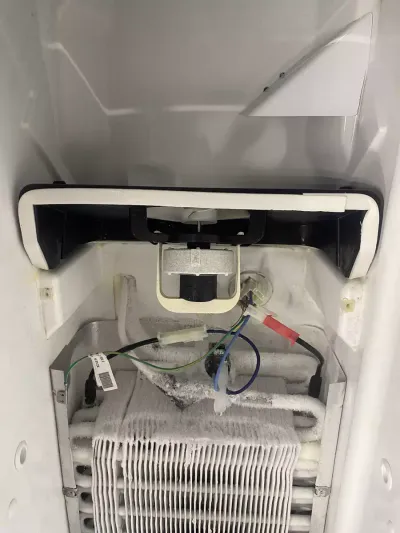

LG Compact All-in-OneThe client sought diagnostics for a washing machine that was given as a gift. It is a compact model with a built-in washing machine and dryer. The washing machine wouldn't turn on at all. We performed diagnostics and found that power was reaching the control board, but it showed no signs of life. The board was replaced. Now the indicator started working, but the machine did not respond to user actions. We replaced the user interface board, which completely fixed the washing machine.

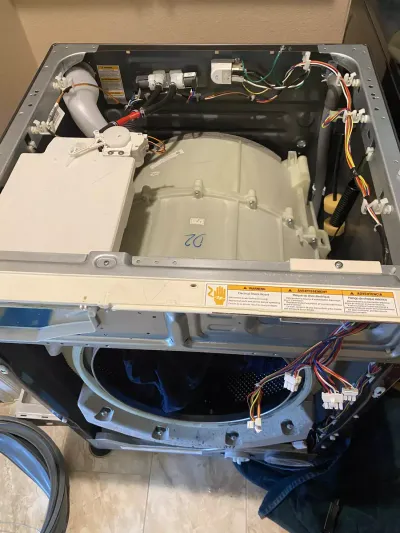

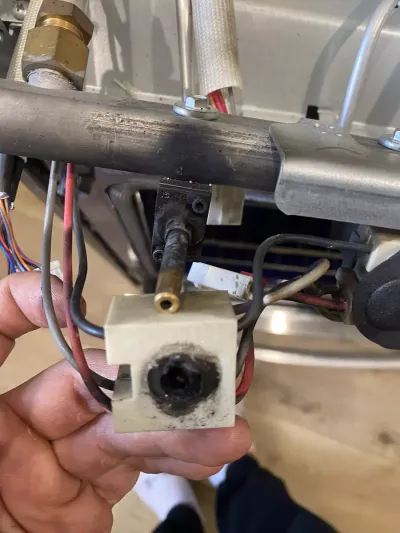

WhirlpoolThe client reported an F6E1 error, which indicates communication problems between the control board and the inverter board that controls the motor of the washing machine. We found that the inverter board had burned out. This often happens if the client overloads the machine with clothes. We replaced the inverter board, and the machine started working again.

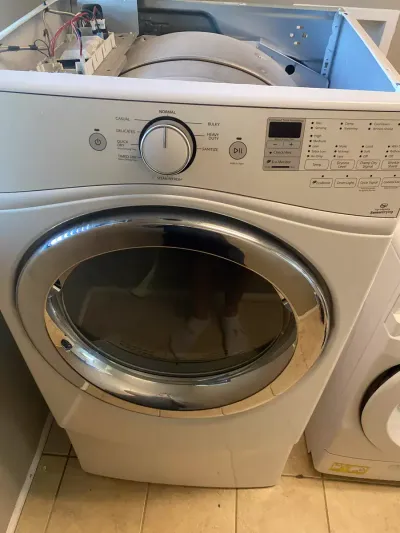

GE Dryer/WasherThe client reported a malfunction that her washing machine was not spinning the drum. We found that the belt had come off. We repositioned the belt, and the washing machine is working. This often happens because a foreign object gets between the motor and the belt. It is important to ensure that items do not fall behind the drum as they can cause this problem.

LGThe client complained about water leaking from under the washing machine. Previously, a technician had replaced the suspension and the upper drum supports, but the cause of the leakage was not identified. Upon detailed inspection of the washing machine, we found that during one of the unbalanced spins, the drum had damaged the outer drum by rubbing a hole through it, causing water to leak during washing. Also, the geometry of the drum had changed, leading to strong vibrations even with replaced/new parts. We advised the client to purchase a new washing machine.

LGThe washing machine was not draining water. We replaced the drain pump.